GENERAL

- The exterior must be weather-tight before electrical systems can be installed CRC R701.2

- Nonmetallic-Sheathed Cable: CEC 334

- NM must be protected in basements and crawl spaces. “Where cable is run at angles with joists in unfinished basements and crawl spaces, it shall be permissible to secure cables not smaller than two 6 AWG or three 8 AWG conductors directly to the lower edges of the joists. Smaller cables shall be run either through bored holes in joists or on running boards.” CEC 334.15.C

- NM must be protected in garages and utility rooms A.M.C.

- NM must be protected near attic access with a permanent ladder/stair ≤ 7’ without ≤6’ CEC 334.23

- Conductor staples: every 4.5’ and 12” from the box CEC 334.30

- # of NM cables in a hole:

- #12-14 (4)

- #6-10 (3)

- #4 & > (1)

- Class 2 wire: required for low voltage lighting CEC 725.121

- Smoke/CO: must be interconnected R314.4 Hardwired R314.6

- All conductors of the same circuit must be installed in the same raceway CEC 300.3.B

- Parallel conductors: must be ≥ 1/0 CEC 310.10.G.1

- Ceiling fan-rated boxes: must be used with ceiling fans CEC 422.18

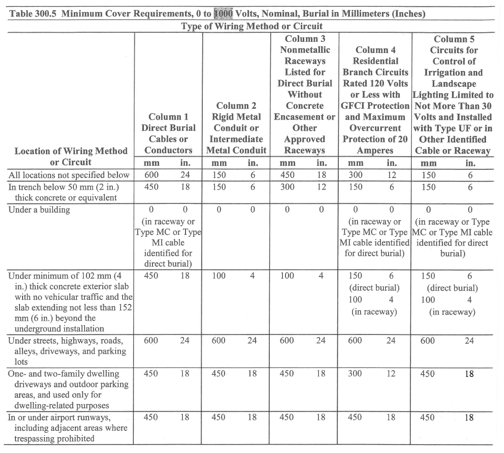

- Conduits below grade: require duct seal at 1 or both ends CEC 300.5.G

Hydro-Massage Bathtubs CEC 680.70

- Dedicated circuit required

- Equipment must be accessible with a supply receptacle accessible only through a service opening. The receptacle shall face within direct view and ≤ 1’ of the opening

- 8 AWG bonding wire is still required when a double-insulated pump motor is installed at the time of inspection to ensure future equipment change out to a non-double-insulated pump motor unless no metallic water pipe is present

- ≥ 8 AWG bonding wire from metallic hot and cold to the terminal on the motor

- GFCI reset can be in an accessible compartment with a motor (12″ from the opening).

Transformers CEC 450

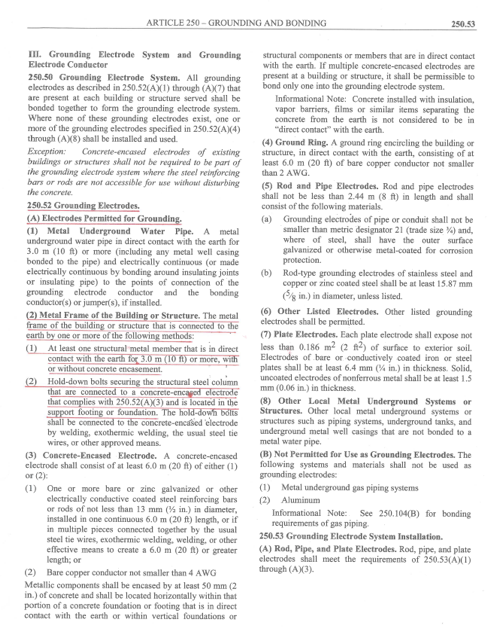

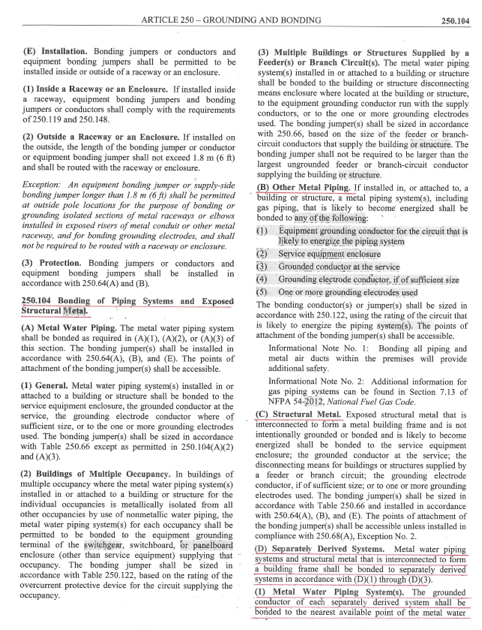

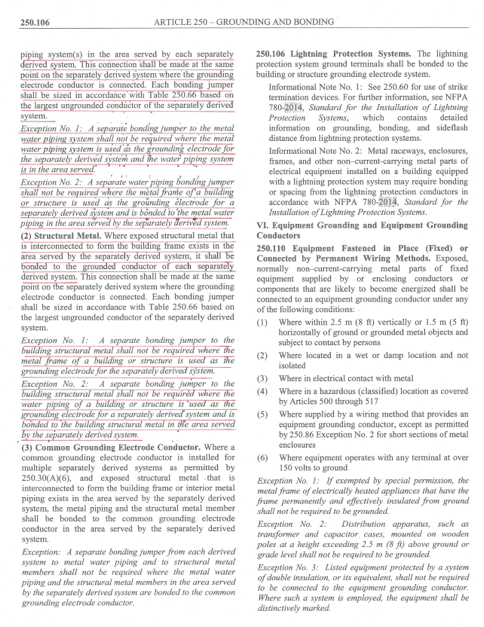

- Bond Metal Water Piping CEC 250.104

- Bond Other Metal Piping CEC 250.104

- Bond Structural Metal CEC 250.104

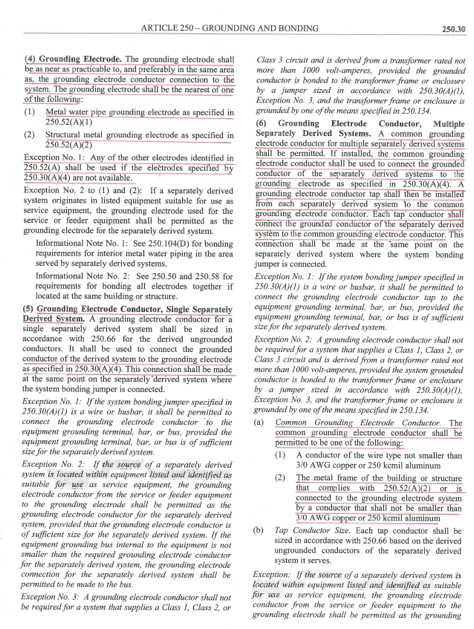

- Grounding electrode: A common grounding electrode conductor for multiple separately derived systems shall be permitted. A grounding electrode conductor tap shall then be installed from each system CEC 250.30.6

- Transformer Vault: CEC 450.42

- 3-hour construction

- 4” concrete slab

- Outswing door with panic hardware

Knob-and-Tube Wiring CEC 394

- Protected by insulating tubes 3” beyond wood member

- 3” clearance between conductors

- 2” clearance from metal (raceway, etc.)

- 1” clearance between conductor and surface over which it passes

- Supported 6” on each side of tap/splice and every 4.5’

- K&T may not be extended. BO

- Insulation in contact with K&T: letter from licensed electrician certifying it is safe for insulation contract. Sign posted in English & Spanish at attic entrance stating concealed K&T present

Liquidtight Metal LFMC CEC 350

- Exposed or concealed where required for flexibility or protection from liquids, vapors, solids

- Not permitted: subject to physical damage

- Bends: < 360 degrees

- Secured: 12” from the box and every 4.5’

Liquidtight Nonmetal LFMC CEC 356

- Exposed or concealed where required for flexibility or protection from liquids, vapors, solids

- Not permitted: subject to physical damage; lengths > 6’

- Bends: < 360 degrees

- Secured: 12” from the box and every 3’

Laundry Rooms

- Dedicated 20 amp circuit for receptacle only CEC 210.52.F

- Lighting: All HE lighting CEC 150.K.1.C

- GFCI: now required in all “laundry areas” CEC 210.8

- Vacancy sensor: required on at least 1 light CEC 150.K.2.J

Lighting

- Recessed down-lights: IC, AT, gasketed CEC 150.K.1.C

- All HE lighting CEC 150.K.1.C

Vacancy Sensor/Dimmer Requirments CEC 150.K.2.J

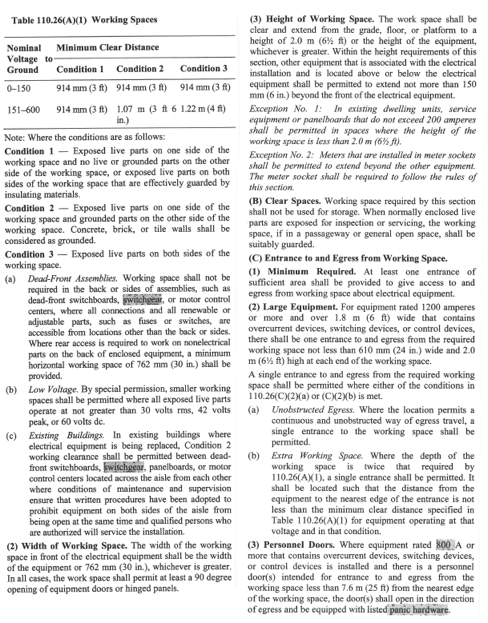

- Closets < 70 sq ft – not required

- Hallways and stairs – not required

- All other switches must be a VS or dimmer

- At least 1 VS in the following:

- Bathrooms – Garages – Utility rooms – Laundry

- EMCS can replace a dimmer

- A multi-scene programmable controller can replace a dimmer

- EMCS can replace a VS

Outdoor Lighting CEC 150.K.3

- Required at all doors to exterior CEC 210.70.A.2

- All HE lighting CEC 150.K.1.A

- Operation: manual ON/OFF CEC 150.K.3

- Plus 1 of the following: CEC 150.K.3

- Photocell and motion sensor

- Photocell and automatic time switch

- Astronomical time clock

- Energy management control system

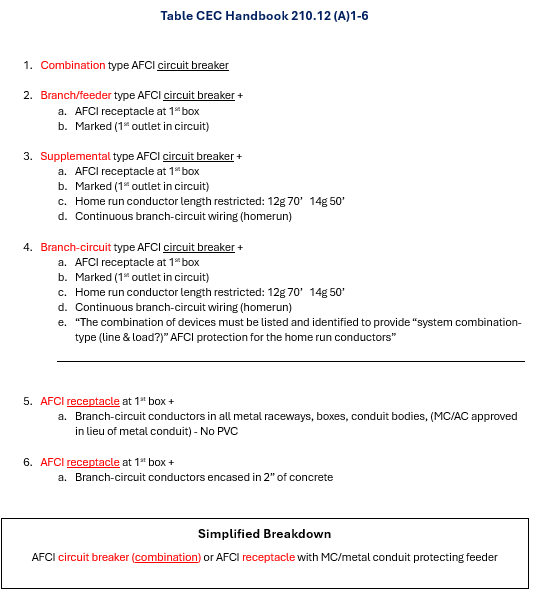

AFCI: All minus the following: Baths – garages – exterior – 240 volt circuits – attics CEC 210.12

GFCI CEC 210.8

- Garage receptacles: GFCI – 20 amp – No AFCI requirements – ALL garage receptacles must be GFCI protected, including 240 volt (non-hardwired EV) for other than dwelling units – 1 receptacle per vehicle stall

- All bathroom receptacles

- Crawl spaces and basements

- Crawl space lighting outlets

- All receptacles < 6′ from the sink, including commercial (refer, dishwasher, disposer, range/oven)

- All kitchen/dining room/breakfast nook countertop receptacles

- All exterior receptacles

- The GFCI reset button must be readily accessible

Panel

- The panel must be labeled CEC 110.22.A

- Knockouts must be filled CEC 110.12.A

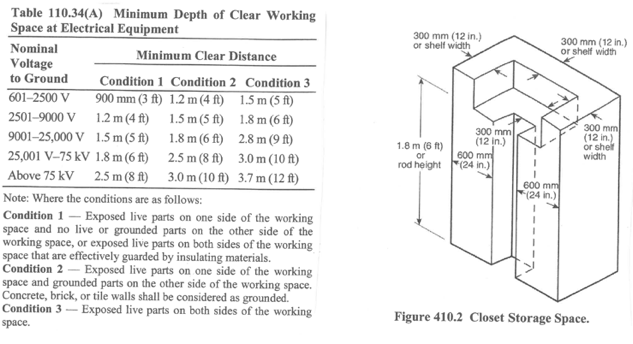

- Panel Clearances: CEC 110.26

- Max breaker height ≤ 6’7” CEC 404.8

- Isolate neutral from EGC at subpanel CEC 250.24.A.5

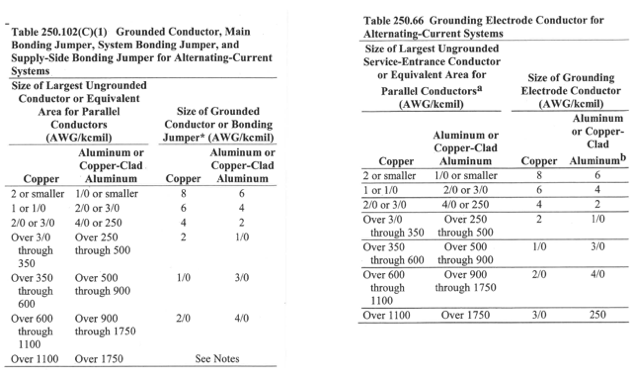

- Bonding: ground rod CEC 250.52.5 water heater CEC 250.104 water main AMP

- Subpanel & main service panel upgrades require space to be reserved for future electrical upgrades. CEC 408.2 requires space for the following:

- Heat pump water heaters.

- Heat pump space heaters.

- Electric cooktops/ovens.

- Electric clothes dryers.

Receptacles

- GFCI CEC 210.8 – AFCI CEC 210.12 – TR CEC 406.12 – Polarity CEC 200.10.B

- 15 amp receptacle ok on 20 amp circuit MI/ CEC TABLE 210.21(B)(3)

- Receptacle spacing: (2/4’ & 6/12’) CEC 210.52.C.1

- Hallways: ≥ 10’ requires a receptacle CEC 210.52.H

- Exterior receptacles: CEC 210.52.E

- In-use covers and must be Heavy Duty CEC 406.9.B GFCI CEC 210.8

- TR CEC 406.12

- 15 or 20 amp, ≤ 6.5’ above grade

- Porch/deck: Receptacle required at a door ≤ 6.5’ above grade CEC 210.52.E.3

- Garages: 20 AMP – 1 receptacle per car CEC 210.52.G

- TR: all must be tamper-resistant CEC 406.12

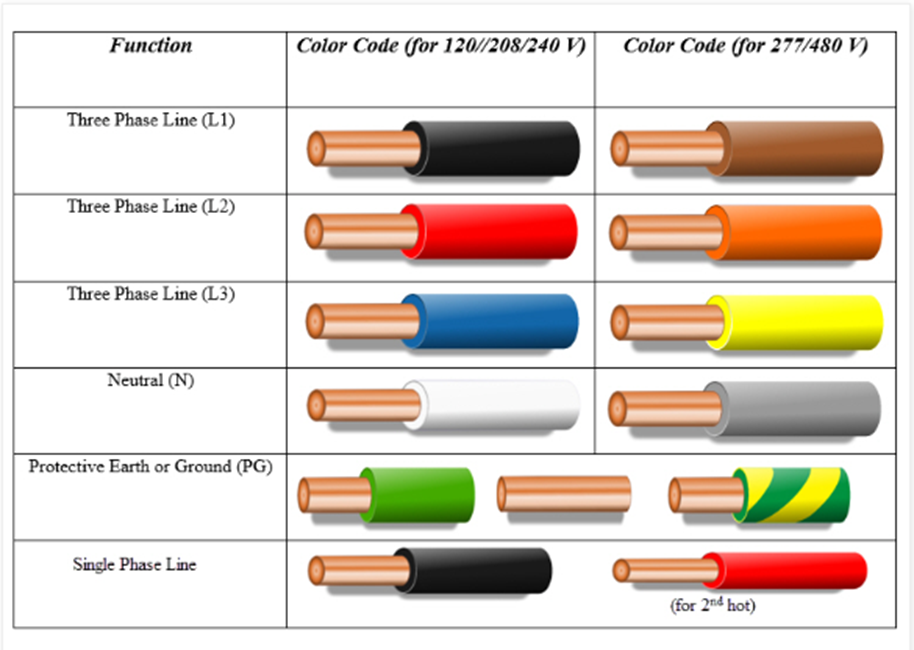

Conductor Markings

AWG: American Wire Gauge

SE: Service Entrance

T: Thermoplastic (PVC)

N: Nylon Jacket

H: Heat-Resistant (75°)

HH: High Heat-Resistant (90°)

W: Water-Resistant

U: Underground

SR: Sunlight-Resistant

-2: (90°)

XHHW: Cross-Linked Polyethylene High Heat-Resistant Water-Resistant

XHH: Flame-Resistant, Water-Resistant, Thermoset (90°)

XHHN: Flame-Resistant, Water-Resistant, Thermoset, Nylon Jacket (90°)

XHHW: lame-Resistant, Water-Resistant, Thermoset, (75° wet & 90° dry)

XHHW-2: Flame-Resistant, Water-Resistant, Thermoset, (90°)

XHWN: Flame-Resistant, Water-Resistant, Thermoset, (75° wet & 90° dry)

XHWN-2: Flame-Resistant, Water-Resistant, Thermoset, (90°)

RHH: Flame-Resistant, Thermoset (90°)

RHW: Flame-Resistant, Water-Resistant, Thermoset (75°)

RHW-2: Flame-Resistant, Water-Resistant, Thermoset (90°)

THHN: Flame-Resistant, Heat-Resistant, Thermoplastic (90°)

THHW: Flame-Resistant, Heat-Resistant, Water-Resistant, Thermoplastic (75° wet & 90° dry)

THW: Flame-Resistant, Heat-Resistant, Water-Resistant, Thermoplastic (75°)

THW-2: Flame-Resistant, Heat-Resistant, Water-Resistant, Thermoplastic (90°)

THWN: Flame-Resistant, Heat-Resistant, Water-Resistant, Thermoplastic (75°)

THWN-2: Flame-Resistant, Heat-Resistant, Water-Resistant, Thermoplastic (90°)

TW: Flame-Resistant, Water-Resistant, Thermoplastic (60°)

USE: Heat-Resistant, Water-Resistant, (75°)

USE-2: Heat-Resistant, Water-Resistant, (90°)

UF: Underground Feeder, Water-Resistant

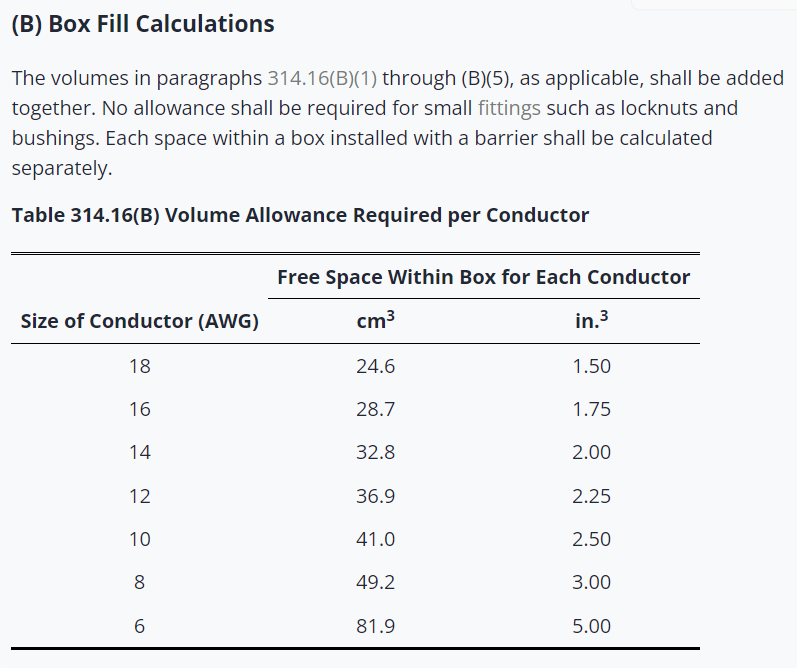

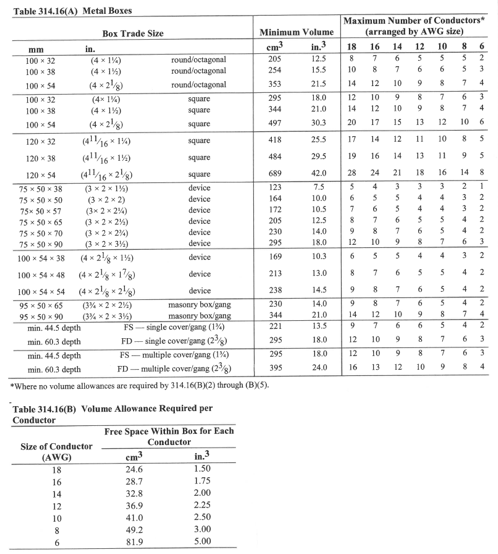

Box Fill CEC 314.16

- Conductor: originates outside the box and terminates/spliced within = counted 1

- Conductor: each that passes through the box = counted 1

- Conductor: loop > 12″ = counted 2

- Clamp: internal = 1 based on the largest conductor in the box

- Stud/Hickey: = 1 based on the largest conductor in the box

- Devices: = 2 each based on the largest conductor connected to that device

- EGC: 0-4 = 1 – 1/4 for each additional – based on the largest conductor in the box

- Link to metal box volume calculations table: https://up.codes/viewer/california/ca-electric-code-2022/chapter/3/wiring-methods-and-materials#314.16_(A)

110.15 High-Leg Marking. On a 4-wire, delta-connected system where the midpoint of one phase winding is grounded, only the conductor or busbar having the higher phase voltage to ground shall be durably and permanently marked by an outer finish that is orange in color or by other effective means. Such identification shall be placed at each point on the system where a connection is made if the grounded conductor is also present. (We will probably never see a high-leg configuration)

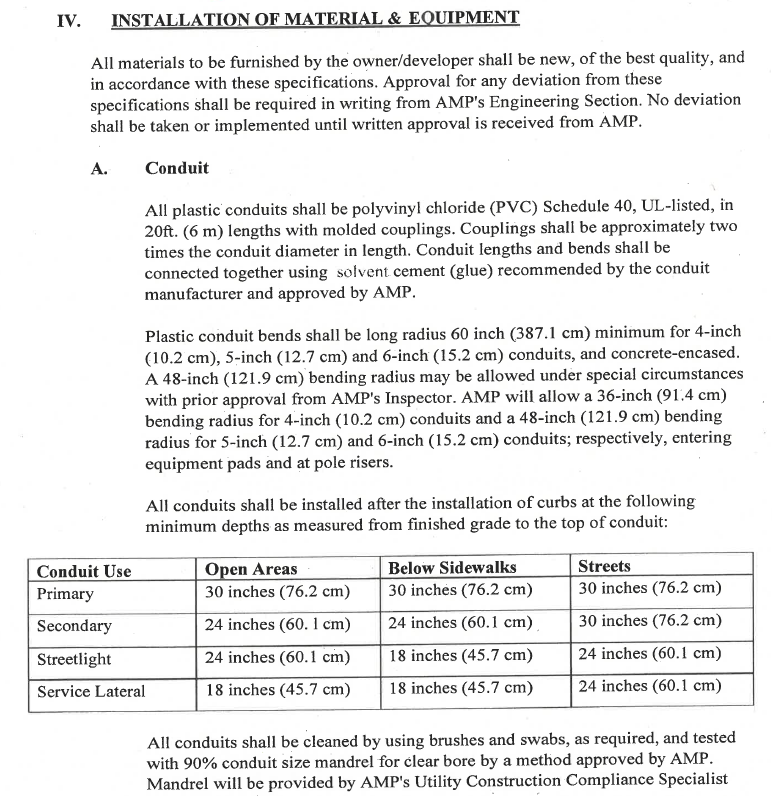

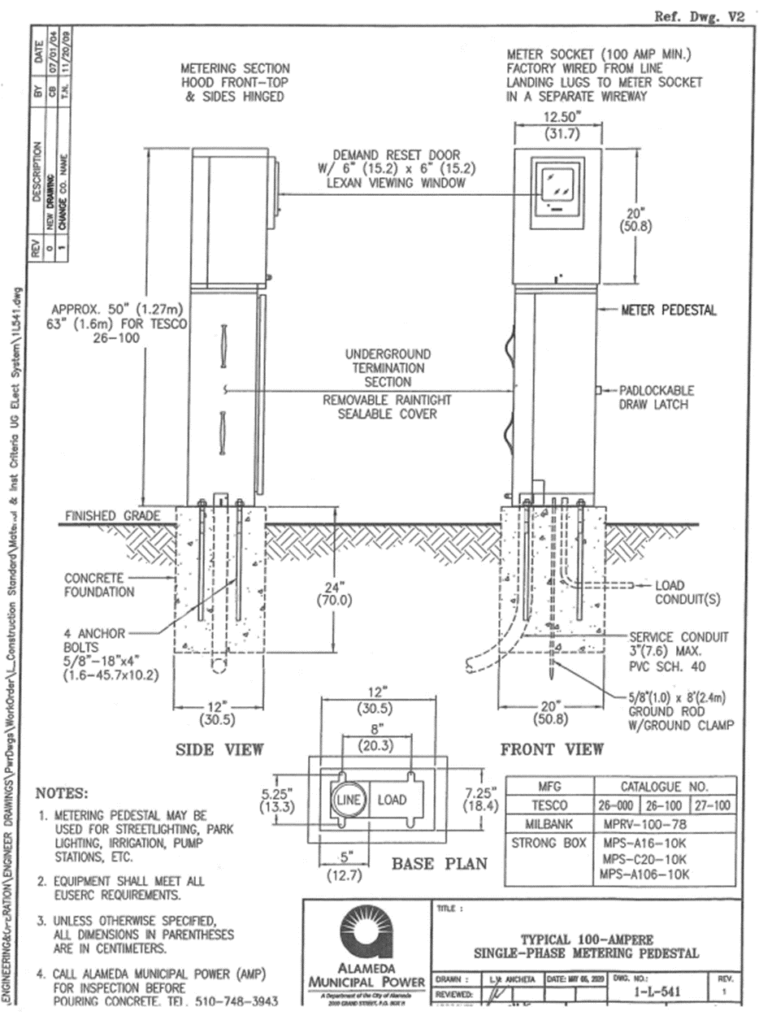

AMP Under Ground Requirements