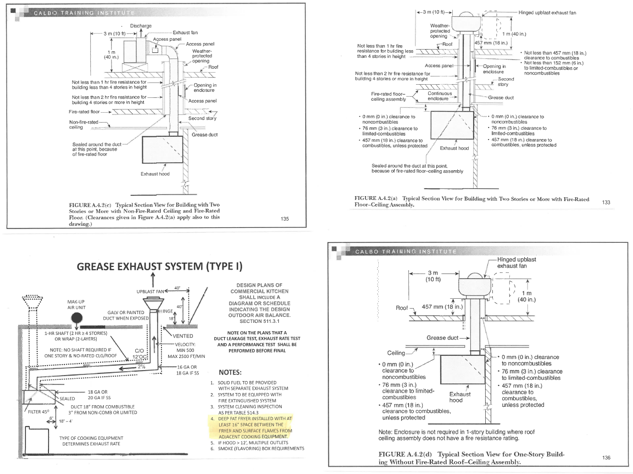

Hood Type 1 (grease exhaust system)

General

- Design, construction, and workmanship shall comply with accepted engineering practices and shall be of such character as to secure the results sought to be obtained by this code. CMC 309

- ¼” slope — > 75’ = 1” slope

- 1 hr shaft (2 hr if 4 or > stories) or 2 layers of fire wrap. No shaft is required if 1 story and no rated ceiling/roof CMC 510.7

- Galvi or painted duct required when exposed CMC 510.6.1

- Hood material: 18ga or 20ga if SS CMC 508.3

- Duct material: 16ga or 18ga if SS CMC 510.5

- Hood filter 45° CMC 509.2.3.3

- Duct 18” from combustible – 3” from non/limited combustible – 6” from non/limited combustible in the shaft. Wood stud wall with 5/8” type X = combustible CMC 510.7.3

- Provide a cleanout every 12’ horizontal – top with vertical – at each floor – at each change of direction CMC 510.3

- Clean out signs “ACCESS PANEL – DO NOT OBSTRUCT” CMC 510.1.5

- 40” to top of rooftop vent cap – 18” to hinge CMC 510.9.1(8)(b)

- Duct termination must be 10’ from a property line and all air intake openings CMC 510.9 roof 510.9.2 wall

- Fire extinguisher system required (Ansul – FD inspection)

- Makeup air (Ansul interlink) CMC 511.3

- Duct test: 100-watt light – air test 1” water column for 20 min – water test 1,500 psi pressure washer CMC 510.5.6 – ASHRAE 154

- Grease reservoir CMC 510.8.1

- Air balance report CMC 407.3

Deep fat fryers 16” separation to open flame cooking equipment or with 8” high tempered glass/steel barrier CMC 515.1.1.3