Link to Building in California Water Heater PDF

Gas

- Gas shut-off at appliance upstream from flex ≤ 6’ CPC 1212.5

- Flex line: same room, cannot pass through walls, proper compression fittings CPC 1212.3.1

- Sediment trap: 3” drip leg – (see photos) CPC 1212.9

- EQ valve: required with a gas line change. BO

Electrical

- Bonding #6 (hot –> cold –> gas) CPC 1211

- Disconnecting means: plug, switched, circuit breaker with lockout CEC 427.55 and CEC 422.33 and CEC 422.31 and M.I.

Combustion Air/Venting

- Direct Vent: all air for combustion must be derived directly from the outdoors CMC definitions

- Combustion air: CPC 506

- Venting/Termination: CPC 509 and 509.5.4 – chimney termination CPC 509.6.2 – B-vent termination CMC 802.6.2

- Where the vent connector used for an appliance having a draft hood for a Category 1 appliance is located in or passes through an unconditioned area, attic, or crawl space, that portion of the vent connector shall be listed as Type B/L CMC 802.10.1.1

- Vent connection with ≥ 3 screws (single wall) M.I.

- PVC vent must have contrasting colored primer – 2% slope back to unit – length, and # of fittings per MI CMC 802.4.2

- B-Vent

- One offset ≤ 60° from vertical. Total horizontal offset = 75 % of the total height CPC 509.6.3.2

- B-vent connector: 1:1 ratio vertical to horizontal. No dips or sags CPC 509.10.7.2

- Vent Connector: Max Horizontal Length CMC 803.2.1

18″ in length per inch in diameter

Diameter Max Length

3″—————-4.5′

4″—————-6′

5″—————-7.5′

6″—————-9′

7″—————-10.5′

8″—————-12′

General

- A valid permit and plans must be on-site R106.3.1

- Manufacturer’s instructions must be left with the unit CRC R106.2

- Vacuum relief device: required with new code 2020 – not enforced at this time CPC 608.7 504.6

- WH installed in nail salon/barber shop/auto repair etc… must be direct vent NFPA 30A

- Clearances: MI

- Bed/bath install: listed, self-closing, gasketed, ext combust air – direct vent is exempt CPC 504.1-2

- Pan: required with potential water damage CPC 507.5 and CMC 305.4

- Pipe insulation: – hot and cold 1st 5′ (tanked unit) – 8’ for commercial CEC150.J.2

- Insulate ALL hot wall lines CPC 609.12

- Temperature Pressure Relief Valve: terminate 6-24” CPC 608.3-5 Terminate to the exterior (sloped) or air gap to the drainage system. No sump well

- Watts 210: verify pressure relief valve required on cold water line CPC 608.3-5

- Shut off valve: full-way required on cold pipe CPC 606.2

- Straps: top 1/3 – bottom 1/3 – 4” above controls CPC 507.2

- Garage install: ≥ 18” off the floor, protection from damage (does not apply to modern appliance – sealed combustion chamber) CPC 507.13

- Condensate drain: see condensates

- Manufacturer’s instructions are required to be left with the unit CPC 507.24

- Electric Tankless Requirements

- Point of use electric resistance water heater(s) are allowed in dwellings of area ≤500 SF per Energy Code Sections 150.1(c)(8) Exception #2 & 150.0(j), Residential Appendix RA4.4.1 & RA4.4.5, and CPC Section 609.12.2 under the following conditions:

- ½” hot water pipe is limited to ≤10’ per water heater AND must have ½” thick minimum insulation

- ¾” hot water pipe is limited to ≤5’ per water heater AND must have ¾” thick minimum insulation.

- Point of use electric resistance water heater(s) are allowed in dwellings of area ≤500 SF per Energy Code Sections 150.1(c)(8) Exception #2 & 150.0(j), Residential Appendix RA4.4.1 & RA4.4.5, and CPC Section 609.12.2 under the following conditions:

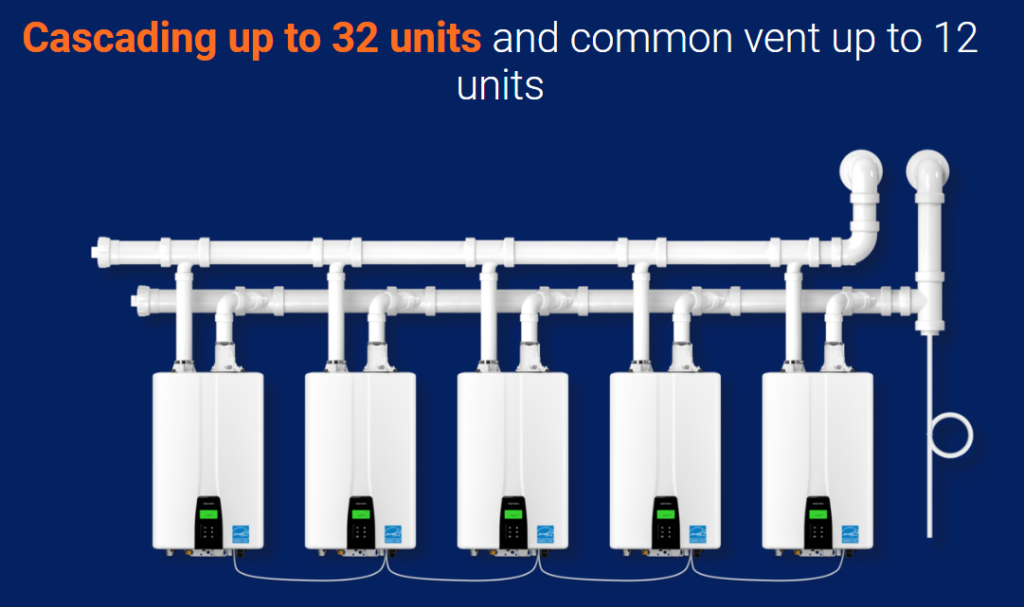

Cascading Tankless Installation Requirements (Navien)

Common Vent Collar with Back-Draft Damper

- Install per manufacturer’s instructions

- A common vent collar is required with shared vents

- Link to Navien installation instructions here

- Contrasting primer is required with PVC vents (not combustion air vents)

- Unit-to-unit communication wire required

- Sediment trap

- T&Ps must be independent CPC608.5.3

- Bonding at each unit required CPC 1211

- A properly sized gas line is required

- Insulate ALL hot wall lines CPC 609.12